- Economical alternatives to complete Coke Drum replacement

- New coke drum feed inlet device. “The Controlled Dispersion Module” (CDM). It is the best and most cost-effective solution currently in the market.

- Free thermal stress coke drum – “The Floating Drum” design.

- Skirt to Shell junction thermal stress reduction – “The Thermal Control Panel”.

- Coke drum reliability – Evaluation, recommendation, and repairs.

- “Real” double block and purge single isolation valve for Delayed Coker applications.

- Coke drum warm up and cool down issues – Hot Spots (Blowouts).

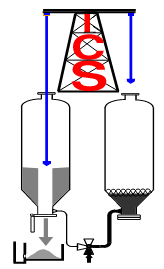

- Fractionator bottom and coke fines removal system.

- Top and Bottom un-heading devices, CFDs, and customized new coke drum side feed entry nozzles (CDM) – Selection, design, and installation.

- Coke drum level detection system.

- Coke drum overhead vapor cooling – system design.

- Coke drum drainage and “plugged” line problems.

- PIT / PAD and Maze – Coke fines management.

- Coked valves issues – Steam purged valves and supplied manifold design.

- Antifoam system design.

- Coke drum vents and vent gas Ejector systems.

- Coke Cutting Systems.

- Coker Heater Operational Reliability Improvements – Spalling, Velocity Steam

- DCU P&IDs Cold-Eyed review